Verbessertes Verdampfungsrohr | Rippenrohr aus Kupfer

VIEW MORE+- ASTM A192 Krümmer

- Die Struktur von Rohrbündelwärmetauschern und Hauptteilen

- LL-Fuß-Rippenrohr vs. L-Fuß-Rippenrohr

- Was ist der Prozesstyp für Spiralrohrschlangen?

- Wissen über Duplex-Edelstahl

- Einführung des Kesselrohrs ASTM A209/ASME SA209 T1

- Funktion und Anwendung von Lamellenheizkörpern

- Welche Auswirkungen haben Wärmeeinflusszonen in Rippenrohren?

- Was verursacht Wärmeeinflusszonen?

- Was ist die Wärmeeinflusszone (HAZ) in Rippenrohren?

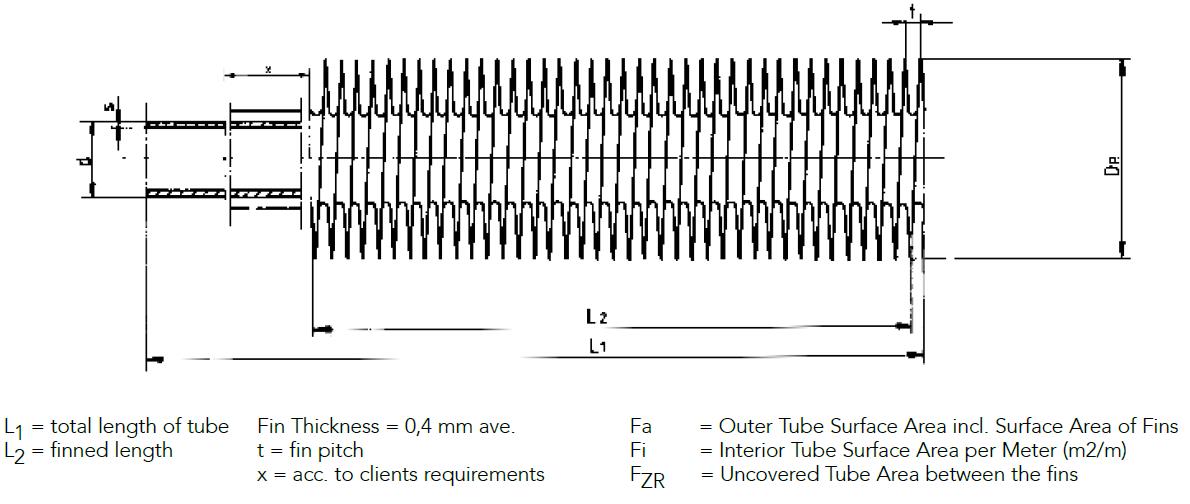

Rippenrohr vom Typ HY|Extrudiertes Rippenrohr

Rippenrohr vom Typ HY, auch extrudiertes Rippenrohr genannt. Ein glattes Kernrohr wird in ein Aluminiumrohr eingeführt und anschließend werden Rippen aus dem Aluminiumrohr extrudiert. Kernrohr durch die Aluminiumhülse weitgehend vor Korrosion geschützt.

Was ist ein HY-Typ Rippenrohr?

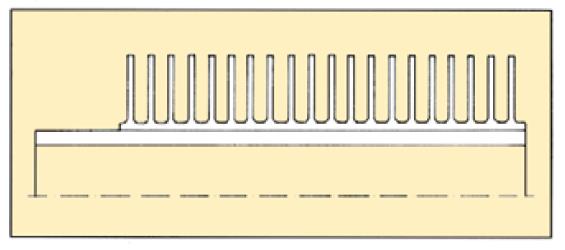

Das HY-Typ Rippenrohr, auch bekannt als extrudiertes Rippenrohr, repräsentiert eine fortschrittliche Technologie in der Wärmeübertragungsindustrie. Bei diesem Verfahren wird ein glattes Grundrohr in ein Aluminiumrohr eingeführt, aus dem anschließend die Rippen extrudiert werden. Diese innovative Fertigungsmethode gewährleistet eine dauerhafte und zuverlässige Verbindung zwischen Innen- und Außenrohr.

Technische Besonderheiten

Die extrusionstechnische Herstellung ermöglicht eine homogene Materialverbindung, die thermisch induzierte Spannungen optimal absorbiert und so einen dauerhaften Kontakt zwischen Grundrohr und Aluminiummantel sicherstellt. Die Rippen weisen eine erhöhte mechanische Stabilität auf, während der Aluminiummantel das Grundrohr umfassend vor Korrosion schützt.

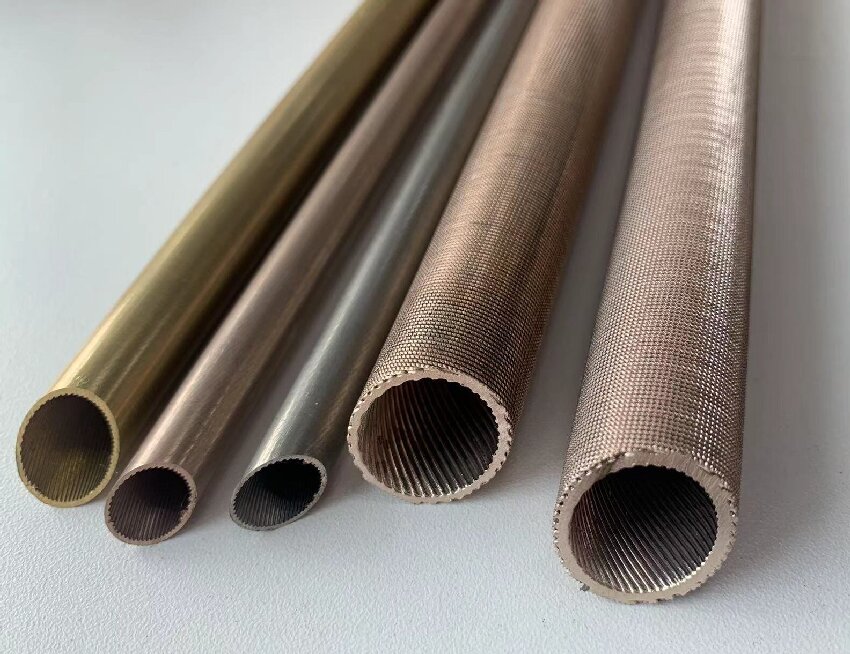

Materialkombinationen für HY-Typ Rippenrohre

Kohlenstoffstähle, niedriglegierte Stähle, Edelstähle, Messing, Kupfer, Kupfer-Nickel-Legierungen, Aluminiumbronze, Nickellegierungen sowie exotische Materialqualitäten

Standardmäßig Aluminium (verschiedene Qualitäten verfügbar) mit optionalen Oberflächenbehandlungen für spezifische Anwendungsanforderungen

Auch extrem dünnwandige Grundrohrmaterialien können verarbeitet werden, was neue Dimensionen im Leichtbau ermöglicht

Anwendungsbereiche

- Erdöl-, Chemie- und Petrochemieindustrie - Zuverlässige Wärmeübertragung in korrosiven Umgebungen

- Erdgasaufbereitung - Effiziente Kühl- und Kondensationsprozesse

- Stahlindustrie - Hochofen- und Konverterkühlsysteme mit maximaler Betriebssicherheit

- Energieerzeugung - Dampfturbinen-Abdampfkondensation in fossilen und Kernkraftwerken

- Klimatisierung - Optimierte Wärmeübertragung für Kältemittel wie Freon, Ammoniak und Propan

- Abfallverbrennung - Langlebige Lösungen für anspruchsvolle Abgaswärmenutzung

- Verdichterkühler - Effiziente Wärmeabfuhr in Kompressionssystemen

- Industrielle Prozesskühlung - Maßgeschneiderte Lösungen für spezifische Kühlanforderungen

Herstellungsprozess

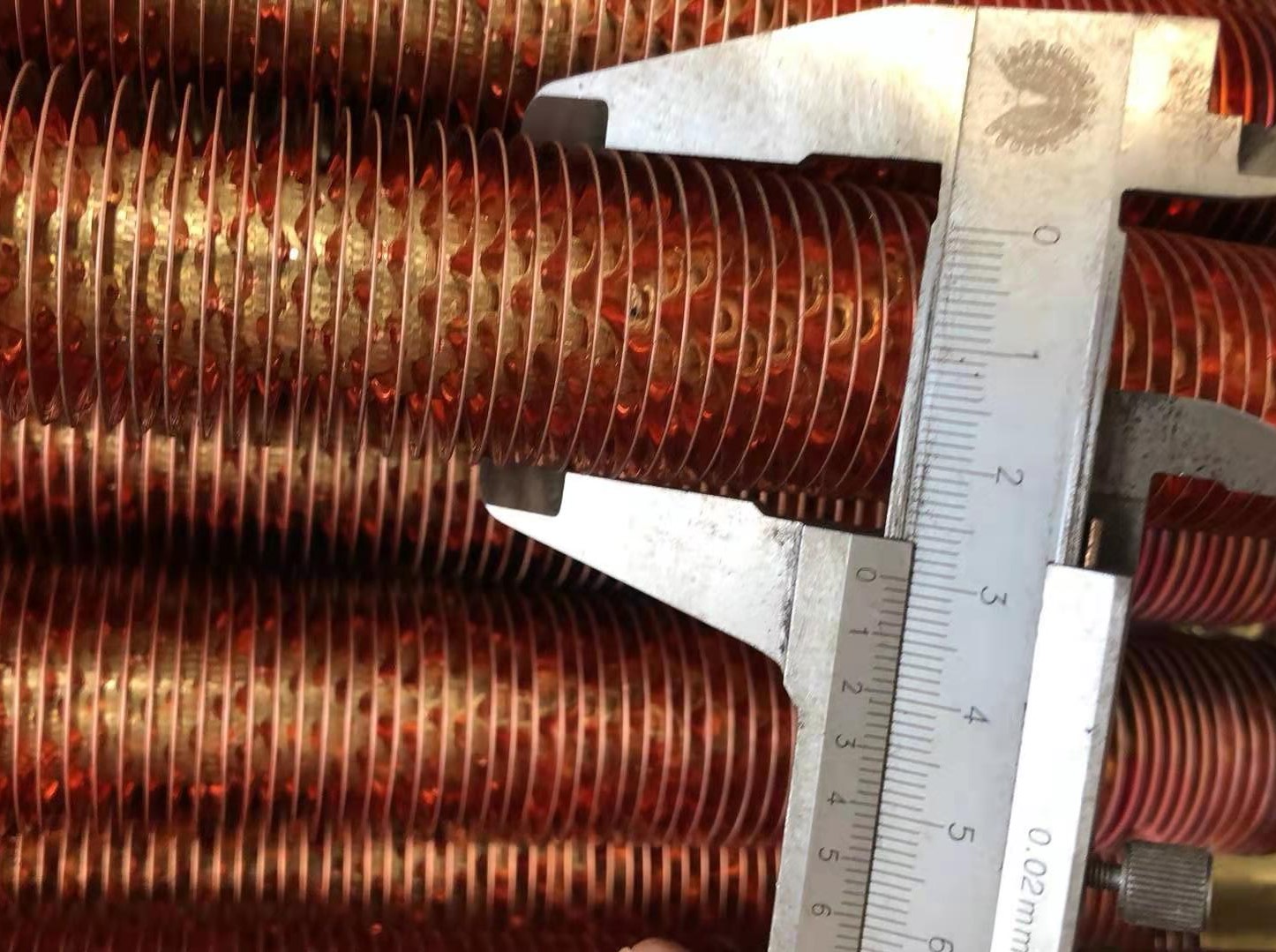

Der Fertigungsprozess beginnt mit einem polierten und entfetteten Grundrohr, das in eine Aluminiumhülse eingesetzt wird. Die Baugruppe durchläuft dann eine Rippenmaschine, die mit drei um 120° versetzten Spindeln ausgestattet ist. Jede Spindel trägt einen Stapel von Platten, die zunächst die Rippen formen und anschließend eine dauerhafte Verbindung zwischen Außen- und Innenrohr herstellen.

Für Anwendungen mit hohen Luftgeschwindigkeiten können die Rippen nach dem Extrusionsprozess gezackt werden, um den Wärmeübergangskoeffizienten durch induzierte Turbulenzen weiter zu erhöhen.

Technische Vorteile

-

Thermische Vorteile

Die vollständige Verbindung zwischen Außen- und Innenrohr eliminiert das Risiko von Kontaktverlusten durch thermische Spannungen. Maximale Betriebstemperatur: 250°C bei konstant bleibendem Wärmeübergangskoeffizienten. Der durchgehende Außenmantel verhindert die Bildung elektrolytischer Paare. -

Mechanische Vorteile

Die extrudierten Rippen weisen eine höhere Steifigkeit auf und widerstehen Handhabungsstößen besser als vergleichbare Typen "G" und "L". Die homogene Materialstruktur gewährleistet optimale Vibrationsbeständigkeit. -

Korrosionsschutz

Der Aluminiummantel bietet umfassenden Schutz für das Grundrohr gegen atmosphärische und chemische Korrosion, was die Lebensdauer signifikant erhöht. -

Wartungsfreundlichkeit

Die glatte Oberfläche und die robuste Konstruktion minimieren Reinigungsaufwand und Wartungskosten.

Leistungsmerkmale

HY-Typ Rippenrohre bieten im Vergleich zu herkömmlichen Rippenrohren eine um 25-40% verbesserte Wärmeübertragungseffizienz bei gleichzeitig reduziertem Druckverlust. Die integrale Verbindungstechnologie gewährleistet eine 100%ige metallurgische Bindung zwischen Grundrohr und Rippen, die auch unter extremen thermischen Zyklen erhalten bleibt.

Spezifikationen und Auswahlkriterien

| Maximale Betriebstemperatur | 250° C |

| Maximaler Betriebsdruck | Abhängig vom Grundrohrmaterial, bis zu 150 bar |

| Rippenhöhen | 6 mm bis 25 mm (standardmäßig) |

| Rippen pro Zoll | 7-11 FPI (standardmäßig), Sonderausführungen möglich |

| Grundrohr-Durchmesser | 15 mm bis 150 mm |

| Oberflächenbehandlungen | Eloxal, Lackierung, oder unbehandelt je nach Anforderung |

Anfragevoraussetzungen für ein präzises Angebot

Um Ihnen ein zügiges und präzises Angebot unterbreiten zu können, benötigen wir folgende Informationen:

- Grundrohrmaterial und benötigte Menge

- Grundrohr-Abmessungen (Durchmesser, Wandstärke)

- Rippenmaterial (standardmäßig Aluminium)

- Rippentyp (glatt, gezackt, spezielle Profile)

- Rippendurchmesser oder -höhe

- Rippenstärke

- Rippen pro Zoll, Meter oder Rippenteilung

- Länge der glatten, unberippten Enden (notwendig zum Einwalzen oder Schweißen in Rohrböden)

- Besondere Oberflächenbehandlungen oder Beschichtungen

- Betriebsbedingungen (Temperatur, Druck, Medien)

Rippenrohr vom Typ HY | Extrudiertes Rippenrohr

-

-

Serpentinenrippenrohre|Biegerippenrohre

VIEW MORE+ -

Rippenrohre mit Randspannung | Aufwickelbare Flossenrohre

VIEW MORE+

请输入搜索关键字

确定